Stainless Steel Feeding Pumps

These top of the range Stainless Steel pumps have been designed for handling liquid pig feed, skimmed milk, whey, slurry type by-products from whisky distilling along with liquid wheat and glucose by-products all of which can be very corrosive and in some cases very abrasive. The pump bodies are fabricated from 6mm 304 Stainless Steel and all other parts such as the impeller, shaft, seal housing and fastenings that are in contact with the pumped medium are also manufactured from stainless steel. Because these pumps have given such satisfaction in service, many have been purchased for other uses around the farm and also in industry for handling many kinds of effluents with particles and solids in suspension, for which purpose their design is eminently suitable. We also produce a smaller version of these pumps built to the same high standards, from 3mm stainless steel. They were specifically designed for transfer duties, but many have been employed on smaller feeding systems.

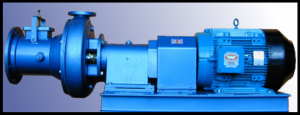

Cast Iron Feeding Pumps

Pumps from this range cost less than the stainless steel, but are built to the same high standard with heavyweight cast iron casing stainless steel shaft, bronze impeller and seal housing. Suitable for feed that contains less corrosive products such as meal and water. Again these have given such satisfaction in service they have been used for many other applications around the farm and in industry.

Macerator Pumps

We have been producing these machines since 1964 and the original purpose was to macerate boiled pigswill to a soup like consistency, enabling it to be pumped by pipelines to the piggeries. After the banning of swill feeding in the UK these machines are still employed for handling the many waste foods that can still be fed to pigs. Other applications for the macerator have also been found in industry, especially in some rendering plants. Due to the nature and temperatures of the products being handled these machines have to be heavily constructed to a very high standard.

Some of the food materials handled successfully by the Macerators are:

Potatoes and other vegetables, fish, bread and bakery waste, chocolate, cheese etc.

Slurry Pumps

Pumping slurry etc from below ground level storage pits, probably presents more problems than any other pumping job on the farm. Not least of these problems is deciding which pump to choose, from the three main types available. Above ground pumps need a foot valve and require priming etc and any air leak in the suction pipe will break the prime and therefore stop the operation.

Submersible pumps

Submersible pumps, where the electric power unit is also submersed overcome the priming problem but are expensive in capital cost, maintain and repair.

We consider the best solution is the long shaft submersible pump as there is no priming hassle and the driving unit, be it electric motor or P T O gear box is accessible for servicing. Our slurry pumps are all of this type and are made in 1 foot (305) mm increments to suit various depths of pits.

They are made in two sizes and various sizes of impeller are available for each.

Wrapper Stripper

These machines have been designed and developed to efficiently separate and remove plastic wrappers from bread cake and similar bakery waste. In operation the bread etc is loaded into the top of the machine, which separates it from the wrappers, which are then pneumatically conveyed into a collection cage ready for disposal. The bread is coarsely kibbled and emerges from the bottom of the machine. In practice most machines are filled using a tractor and fore-end loader.

The bread is loaded into a feed hopper, which is fitted with an electronically controlled mechanism. This releases bread into the stripper at optimum rate. The kibbled bread forms a heap under the machine ready to be removed with the fore-end loader. Alternatively: loading and removal arrangements could be by conveyor.

Throughput can be up to three tons per hour, dependant on the type and condition of product being handled.

Pipes, Valves & Fittings

We can supply from an extensive range of pipes valves and fittings in PVC, Steel and Stainless Steel along with ball, gate and sluice valves in Brass. Motor and Pneumatically operated ball valves in C P Brass and Stainless Steel are also available.